Improper Collision or Mechanical Repairs can have a huge effect on how your vehicle responds in a subsequent collision.

As new vehicles get lighter and lighter it is structural engineering that protects passengers in a collision, not mass. The Insurance Institute for Highway Safety spends a lot of money ($60,000 per car) crash testing new cars to pressure OEMs (original equipment manufactures) to design and build safer cars. However, there is no system used by the insurance companies to confirm that structural repairs have been completed to factory operating limits. This is why you need to know your vehicle’s most important safety feature, the crush zone. Improper repairs after a collision can compromise the structural integrity of the vehicle if not repaired properly causing the vehicle not to perform in the way it was designed by the manufacture.

The body of a vehicle is designed to withstand the shocks of normal driving and to provide safety to occupants in the event of a collision. Vehicle manufacturers design the body so that it will collapse and absorb the maximum amount of energy in a severe collision to protect the occupants. The front and rear body are designed to deform easily which forms a structure that absorbs impact energy.

By Courtesy I-CAR

Apr 22, 2005 – 5:19:00 PM

* This article first appeared in the I-CAR Advantage Online, which is published and distributed free of charge. I-CAR, the Inter-Industry Conference on Auto Collision Repair, is a not-for-profit international training organization that researches and develops quality technical education programs related to collision repair. To learn more about I-CAR, and to subscribe to the free publication, visit https://www.i-car.com.

Proper structural repair is even more critical with airbags than with seat belts. Why? Because the stiffness and crushability of the structure is what tells the airbag sensor when to deploy the airbag. If the sensor has been altered due to a repair, the airbag may not open at the right time. Since the time to deploy the airbag is short, deployment must occur at the right time in order to cushion the occupant.

Car makers take great care to ensure all the structural components work together. The correct flow of crash energy (the “crash pulse”) through the vehicle is imperative. Automakers “tune” the pulse to exactly the right combination of deceleration, time and crush distance for maximum occupant safety.

Car makers take great care to ensure all the structural components work together. The correct flow of crash energy (the “crash pulse”) through the vehicle is imperative. Automakers “tune” the pulse to exactly the right combination of deceleration, time and crush distance for maximum occupant safety.

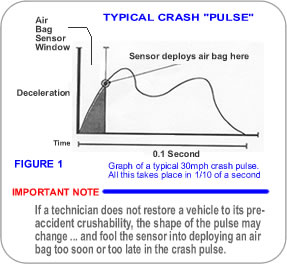

Figure 1is a typical 30 mph barrier crash pulse. The pulse is produced by the deceleration over a period of time after the vehicle hits a solid object. The shape of this pulse is determined by the way each piece of a structure crushes during the accident. The pulse is unique to each make and model of car.

The entire crash pulse takes about 1/10th of a second. During this time occupants move forward. If there are no seatbelts or airbags, the occupants will hit the steering wheel, windshield or dashboard. This normally occurs just before the car completely stops. The occupants continue to travel at the speed they were originally going and only slow down when they hit something. This is what causes serious or fatal injuries to unrestrained occupants. It is often called “the second collision.”

The effect of the seat belt occurs late in the pulse. A seat belt helps slow the occupant down before hitting the interior of the car. The occupant may still hit the interior, but at a much slower speed, greatly reducing the possibility of injury. The car is nearly stopped before the seat belt starts to have an effect. Crushability and the shape of the pulse have some effect, but not as much as with an air bag.

The airbag is inflated very early in the crash in order to cushion the occupant. As it deflates, it slows the occupant down over a relatively long period of time. Figure 2 shows this in action. This makes airbags effective in reducing injuries. It also makes the best use of the pulse or crushability of the structure.

The airbag is inflated very early in the crash in order to cushion the occupant. As it deflates, it slows the occupant down over a relatively long period of time. Figure 2 shows this in action. This makes airbags effective in reducing injuries. It also makes the best use of the pulse or crushability of the structure.

Airbag sensors measure deceleration. If there isn’t enough deceleration, the sensor knows the accident is not severe enough and will not send a deploy signal. If the deceleration is sufficient enough, the sensor instantly deploys the airbag.

Timing is so important that each make and model car has a different shaped pulse. Each sensor is designed to match the crash pulse of the car. Other safety components and the air bag system are also carefully matched for the make and model.

If the vehicle is damaged, it is important to restore the sensor and the structural safety elements to their original conditions. That is why car makers require technicians to:

a) make sure sensors are inspected and replaced when necessary

b) use only part numbers specified for each car

c) make sure all sensors are properly installed

Structural repair is risky for the timing sequence. If the technician does not restore the vehicle to pre-accident crushability, the shape of the pulse may change. This may fool the sensor into deploying the airbag too soon or too late in the crash pulse. For example, a technician can make the structure too stiff by adding reinforcement in a crush zone. This can cause the deceleration to increase too early or too fast. The sensor may then deploy the airbag too soon (see figure 3.)

The opposite is also true. If a structure element is weakened the deceleration may become too slow or too late. The sensor may then deploy the airbag too late (see figure 4.)

Conclusion

ConclusionTechnicians should review everything they have learned about structural repair: straightening, welding, sectioning, when to replace, when to repair, etc. They should keep up with it and use it in their daily work, especially with airbag equipped cars.

Need help now? Call us for immediate service! 702 463-7743